TYPE L NO CLEAN SOLDER PASTES

Multicore CR32 has been formulated as a modest residue

level product for printing and reflow in air. CR32 solder

pastes offer excellent open time and soldering activity with

pale post-soldering residues.

Non-corrosive residues – eliminates the need for

cleaning

Enhanced activity to deal with poor component

solderability

Excellent resistance to solder balling

Wide reflow process window for tin/lead and lead-free

soldering processes

Suitable for fine pitch, stencil printing applications

Excellent slump resistance

Good tack performance and open time

Probe testable residues with reduced false failures

ROL0 to ANSI/J-STD-004

PRODUCT RANGE

Multicore CR32 solder pastes may be supplied with powder

made from most soldering alloys in the Multicore product

range. The most common alloy types are Sn62, Sn63 and

lead free alloys 96SC, 97SC and 96S conforming to the

purity requirements of J-STD-006 and EN 29453. Minimum

order requirements may apply to certain alloy and powder

particle size combinations.

Multicore CR32 flux is a no-clean type L flux and will be

suitable for most assembly processes. It is especially suited

to meet the demands of high volume production processes

using components and boards that have less than the

desirable level of solderability. The activity level of CR32

produces greater tolerance to process variations and lower

tendency to solder balling.

REFLOW GUIDELINES

Any of the available methods of heating to cause reflow

may be used including IR, convection, hot belt, vapour

phase and laser soldering. In most cases the reflow profile

is determined by the requirements of the board &

components and the capability of the oven rather than the

solder paste.

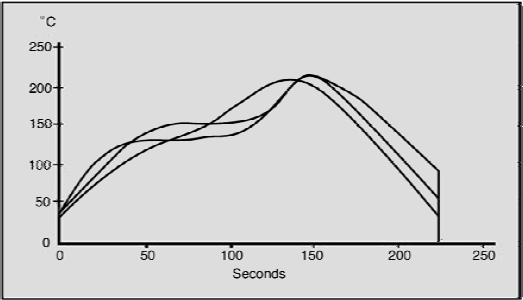

However some general guidelines on the reflow conditions

can be given.

Depending on the thermal demand of the assembly and the

efficiency of the oven used a reflow “soak” profile or a

linear ramp type profile can be used. Usually the process

determines the type of profile required (or achievable).

CR32 solder pastes can be used with either kind of profile.

Excessive preheat time or temperature and/or time above

liquidus will lead to non-coalescence of the solder. The

residues are resistant to charring but may show some

cosmetic deterioration with particularly long and/or hot

profiles.

Generally the reflow profile should allow for a time above

the liquidus temperature of the alloy used of 20-60s above

reflow, however times above liquidus temperature outside of

this range may be necessary for some processes and in most

cases acceptable reflow will be possible in the range 60-90s

above reflow.

Recommended preheat soak zone temperature is 120-160oC,

the length of the preheat step will be determined by the

assembly being soldered; one to four minutes is typical. For

linear ramp profiles the ramp to peak reflow temperature

will typically be between 2.0oC/s to 0.7oC/s

Reflow conditions for lead-free pastes

The reflow conditions are broadly similar to those for

tin/lead pastes. A time above the liquidus temperature

(217°C for 96SC) of 20-60s is typical. Preheat

recommendations are similar to those for tin/lead pastes.

The peak reflow temperature will typically be in the range

235-260°C.

The chart below shows some example profiles for tin-lead

alloy solder pastes which have given good results in practice

using typical process equipment.

Excellent resistance to solder balling

Wide reflow process window for tin/lead and lead-free

soldering processes

Suitable for fine pitch, stencil printing applications

Excellent slump resistance

Good tack performance and open time

Probe testable residues with reduced false failures

ROL0 to ANSI/J-STD-004

PRODUCT RANGE

Multicore CR32 solder pastes may be supplied with powder

made from most soldering alloys in the Multicore product

STENCIL PRINTING

CR32 solder pastes are designed to be used with semiautomatic

or fully automatic stencil printing equipment but

may also be used on manual printing equipment. With type

three powder the paste is capable of giving reproducible

prints with repeatable print height down to 16mil (thou)

pitch, 50:50 pad gap, although finer pitch printing may be

possible where the stencil thickness is optimised for the

finest pitch areas on the board. For 16 mil pitch printing the

use of a 5 mil thick stencil will improve general print-toprint

height consistency and aperture release. Printing at up

to 150mm s-1 can be reliably achieved in production.

Typically most stencil printing processes use metal blades

(squeegees) and these are recommended for fine pitch

printing. The rheology of CR32 solder pastes ensure

excellent definition and slump resistance while maintaining

good roll and drop off behaviour. CR32 pastes do not

require the addition of thinners either before or during use.

It is recommended that product shipped in jars should be

gently stirred for 15 seconds before use.

CLEANING

The residues from Multicore CR32 no-clean solder pastes

are designed to be left on the PCB since they do not pose a

hazard to long term reliability. However, should there be a

specific requirement for residue removal, this may be

achieved using conventional cleaning processes based on

solvents such as Multicore MCF800.

TECHNICAL SPECIFICATION

Solder Powder: The solder powder for Multicore CR32

solder pastes is produced by atomising alloys conforming to

the purity requirements of J-STD-006, EN 29453 or other

national and international standards where relevant.

Careful control of production processes ensures that the

solder powder is at least 97% spherical (aspect ratio <1.5)

and contains less than the minimum level of contaminants

that would adversely affect solder paste performance. A

typical maximum oxide contamination level of 80ppm

(expressed as oxygen in the solder) is regularly achieved or

bettered.

Solder Paste Medium: Multicore CR32 contains a stable

resin system and solvents with high boiling ranges and low

odour.

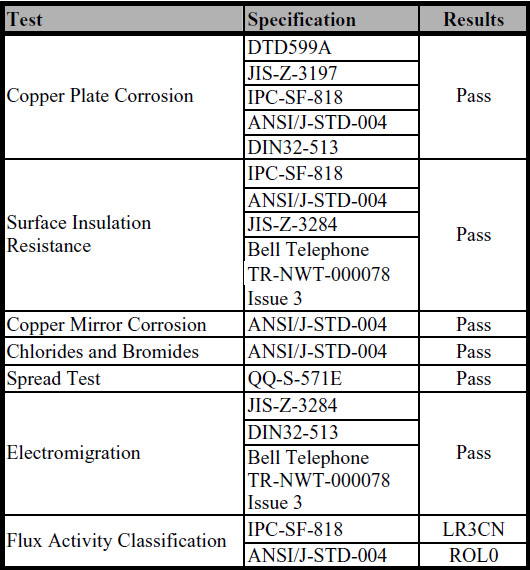

CR32 is classified as Type L flux under IPC-SF-818

specification and passes the surface insulation resistance

requirements for Class 3 (high reliability) products. The flux

testing is summarised in the table below, official test reports

are available on request.

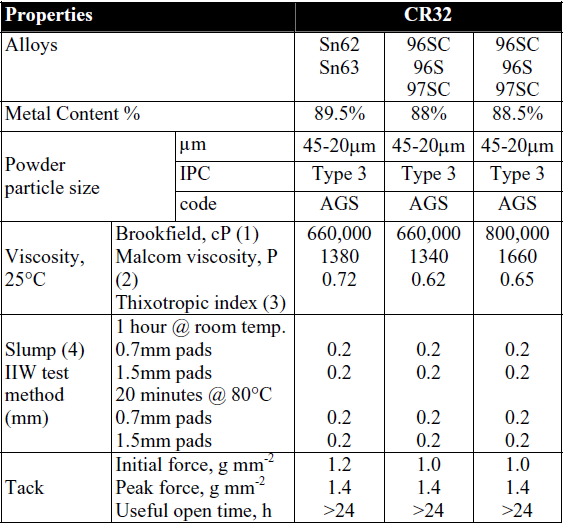

Solder Paste: The properties of a solder paste depend in

part on the metal content, the solder alloy and the solder

powder particle size range. In general terms, increasing

metal content reduces the tendency to slump and reduces the

tackiness of the solder paste while the solder balling

performance improves. The metal content (by weight) of

lead free solder pastes are often somewhat lower than tin

lead solder pastes for similar applications due to the lower

density of lead free alloys.

It is common practice to characterise the rheology of solder

pastes by making a viscosity measurement at a single

specified shear condition. Increasing metal content increases

the measured value and at higher metal contents, decreasing

the mean solder powder particle size can have the same

effect. A more informative indication of the rheological

properties of solder pastes is provided by a plot of viscosity

versus shear rate and these data are summarised as the

“Thixotropic Index” of a paste.

Typical properties of selected Multicore CR32 solder pastes

are as follows. Full details of test methods can be supplied

on request.

(1) Measured at 25°C, TF spindle at 5rpm after 2 minutes.

(2) Measured at 25°C and a shear rate of 6s-1 (typical values)

(3) The Thixotropic Index (TI) is defined as:

TI=log (viscosity at 1.8s-1/viscosity at 18s-1), typical values.

(4) The slump data are expressed as the minimum spacing between pads of

the size shown that does not allow bridging

(5) Tack data are derived from comparative laboratory tests and do not

necessarily relate directly to particular user conditions.

PACKAGING

Containers: Multicore CR32 solder pastes are supplied in: