PRODUCT DESCRIPTION

LOCTITE GC 10 provides the following product characteristics:

Technology No-clean and Halogen-free Solder Paste

Application Pb-free soldering

LOCTITE GC 10 solder paste is a halogen free, no-clean, low voiding,

Pb-free solder paste specially formulated to provide added long term

stability over a range of temperature conditions. The enhanced paste

stability created through its novel formulation strategy, increases both

field application yields and on-line paste utilization.

LOCTITE GC 10 also shows excellent solderability when reflowed in

both air and nitrogen across a wide range of challenging surface

finishes and component metallizations including immersion Ag,

OSP-Cu, ENIG and CuNiZn. It supports excellent reflow to overcome

industry wide HiP and NWO challenges. The new flux chemistry will

protect the solder longer, improve coalescence and optimize wetting

performance, allowing for very shiny solder joints.

LOCTITE GC 10 is suitable for use with industry standard SAC alloys.

FEATURES AND BENEFITS

● Halogen-free flux: passes IC with pretreatment IPC-TM-650

2.3.34/EN14582

● Halogen-free flux classification: ROL0 to ANSI/J-STD-004 Rev.

B

● Printing: Fine pitch capability (0.3 mm), stencil life (>16 hours),

and abandon time (>8 hours)

● Improved paste transfer efficiency

● Printing: Suitable for high speed printing up to 125 mms-1

● Improved reflow process window (high soak temperatures and

time) with superior coalescence and wetting

● Very shiny Pb-free solder joints over wide range of reflow

● Colorless residues for easy post-reflow inspection

● Residues pint-testable after 5x reflow

● Will allow online paste utilization protocols to be re-written

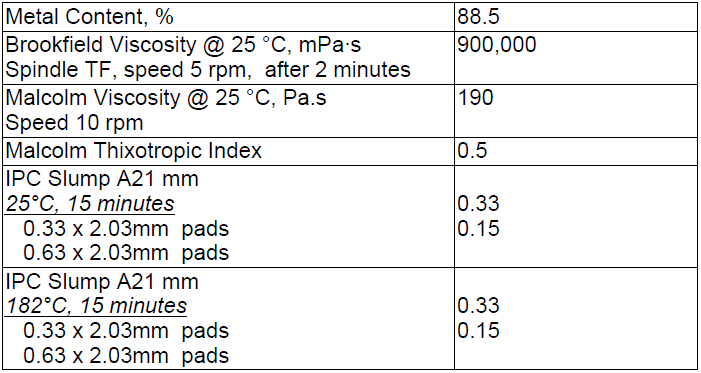

TYPICAL PROPERTIES

Based on type 4 powder.

Solder Paste Typical Properties

DIRECTIONS FOR USE

Printing:

1. LOCTITE GC 10 is available for stencil printing with type Type 4

powder.

2. Printing at speeds between 25 to 125 mms-1 can be achieved

using laser cut, electropolished or electroformed stencils with

metal squeegees.

Reflow:

1. Any of the available methods of heating to cause reflow may be

used including IR, convection, hot belt, vapor phase and laser

soldering.

2. Typical profiles that have shown good performance are shown

below.

Reflow Profile

Cleaning:

1. LOCTITE GC 10 solder pastes are no-clean and are designed to

be left on the PCB in many applications post assembly since it

does not pose a hazard to long term reliability.

2. Should there be a specific requirement for residue removal, this

may be achieved by using conventional cleaning processes

based on solvents such as LOCTITE MCF800.

3. For stencil cleaning and cleaning board misprints, LOCTITE SC-

01 Solvent cleaner is recommended.

4. Residues are easily removed in batch and in-line aqueous

cleaners even up to three days post reflow.

5. Cleaning of some assemblies is best conducted in an ultrasonic

bath.

6. Tap water is not recommended for rinsing, since ionic impurities

present in tap water can lead to reduced reliability of the

assembly.

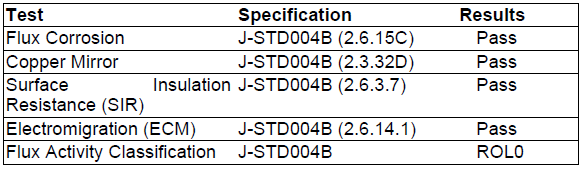

RELIABILITY PROPERTIES

Solder Paste Medium:

LOCTITE GC 10 medium contains a stable resin system, slow

evaporating solvents and with minimal odour. The formulation has

been tested to the requirements of the ANSI/J-STD-004B for a type

ROL0 classification specifications.

PACKAGING

LOCTITE GC 10 is available in both jars and in semco cartridges, other

types of packaging may be available on request.

Storage:

Optimal storage :5 to 25ºC

Storage information may be indicated on the product container

labelling. Material removed from containers may be contaminated

during use. Do not return products to the original container. Henkel

Corporation cannot assume responsibility for product which has been

contaminated or stored under conditions other than those previously

indicated. If additional information is required, please contact your

local Technical Service Centre or Customer Service Representative.

Shelf Life:

Provided that LOCTITE GC 10 is stored in the original container, a

minimum shelf life of 365 days at 5 to 25˚C or 31 days at 40°C can

be expected.

Air shipment is recommended to minimise the time the containers are

exposed to higher temperatures.

DATA RANGES

The data contained herein may be reported as a typical value and/or a

range. Values are based on actual test data and are verified on a

periodic basis.

GENERAL INFORMATION

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Not for Product Specifications

The technical information contained herein is intended for reference

only. Please contact Henkel Technologies Technical Service for

assistance and recommendations on specifications for this product.

Conversions

(°C x 1.8) + 32 = °F

kV/mm x 25.4 = V/mil

mm / 25.4 = inches

μm / 25.4 = mil

N x 0.225 = lb

N/mm x 5.71 = lb/in

N/mm² x 145 = psi

MPa x 145 = psi

N·m x 8.851 = lb·in

N·m x 0.738 = lb·ft

N·mm x 0.142 = oz·in

mPa·s = cP

Disclaimer

Note:

The information provided in this Technical Data Sheet (TDS) including the

recommendations for use and application of the product are based on our

knowledge and experience of the product as at the date of this TDS. The product

can have a variety of different applications as well as differing application and

working conditions in your environment that are beyond our control. Henkel is,

therefore, not liable for the suitability of our product for the production processes

and conditions in respect of which you use them, as well as the intended

applications and results. We strongly recommend that you carry out your own

prior trials to confirm such suitability of our product.

Any liability in respect of the information in the Technical Data Sheet or any other

written or oral recommendation(s) regarding the concerned product is excluded,

except if otherwise explicitly agreed and except in relation to death or personal

injury caused by our negligence and any liability under any applicable mandatory

product liability law.

In case products are delivered by Henkel Belgium NV, Henkel Electronic

Materials NV, Henkel Nederland BV, Henkel Technologies France SAS and

Henkel France SA please additionally note the following:

In case Henkel would be nevertheless held liable, on whatever legal ground,

Henkel’s liability will in no event exceed the amount of the concerned delivery.

In case products are delivered by Henkel Colombiana, S.A.S. the following

disclaimer is applicable:

The information provided in this Technical Data Sheet (TDS) including the

recommendations for use and application of the product are based on our

knowledge and experience of the product as at the date of this TDS. Henkel is,

therefore, not liable for the suitability of our product for the production processes

and conditions in respect of which you use them, as well as the intended

applications and results. We strongly recommend that you carry out your own

prior trials to confirm such suitability of our product.

Any liability in respect of the information in the Technical Data Sheet or any other

written or oral recommendation(s) regarding the concerned product is excluded,

except if otherwise explicitly agreed and except in relation to death or personal

injury caused by our negligence and any liability under any applicable mandatory

product liability law.

In case products are delivered by Henkel Corporation, Resin Technology

Group, Inc., or Henkel Canada Corporation, the following disclaimer is

applicable:

The data contained herein are furnished for information only and are believed to

be reliable. We cannot assume responsibility for the results obtained by others

over whose methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production methods mentioned

herein and to adopt such precautions as may be advisable for the protection of

property and of persons against any hazards that may be involved in the handling

and use thereof. In light of the foregoing, Henkel Corporation specifically

disclaims all warranties expressed or implied, including warranties of

merchantability or fitness for a particular purpose, arising from sale or use

of Henkel Corporation’s products. Henkel Corporation specifically

disclaims any liability for consequential or incidental damages of any kind,

including lost profits. The discussion herein of various processes or

compositions is not to be interpreted as representation that they are free from

domination of patents owned by others or as a license under any Henkel

Corporation patents that may cover such processes or compositions. We

recommend that each prospective user test his proposed application before

repetitive use, using this data as a guide. This product may be covered by one or

more United States or foreign patents or patent applications.

Trademark usage

Except as otherwise noted, all trademarks in this document are trademarks of

Henkel Corporation in the U.S. and elsewhere. ® denotes a trademark

registered in the U.S. Patent and Trademark Office.

Reference N/A

Americas Europe Asia

+1.888.943.6535 +32.1457.5611 +86.21.3898.4800

For the most direct access to local sales and technical support visit: www.henkel.com/electronics